These are any devices

that restrict flow causing significant pressure drop in a fluid without

involving any work or significantly accelerating the fluid. A common example of

a throttling device is the valve in the common kitchen faucet which reduces the

pressure of the water main to atmospheric pressure.

As most throttling valves produce negligible changes in the potential and kinetic energies, the energy balance simplifies as shown:

Usually, the fluid passing through a throttling device is moving so

rapidly that it does not remain within the device long enough for heat transfer

to take place. Heat transfer can be considered negligible, thus the above equation simplifies as:

Since enthalpy is constant, this is an isenthalpic process. During a throttling process,

the variation of temperature as a result of the decrease in pressure is called

the Joule-Thomson coefficient, µ.

In a throttling process,

the temperature of a gas may decrease or increase depending on its initial

state as shown:

The temperature at which

Joule-Thomson coefficient changes sign is called an inversion temperature.

At higher temperatures µ <

0 and at lower temperatures µ > 0. Consequently, cryogenic applications

require gas temperature to be lower than the inversion temperature.

Most gases have an

inversion temperature higher than room temperature. Hydrogen, however, has an

inversion temperature of − 80°C. Thus, to liquefy hydrogen, it is first necessary

to decrease its temperature below − 80°C using liquefied nitrogen and then

decrease its pressure by a throttling process.

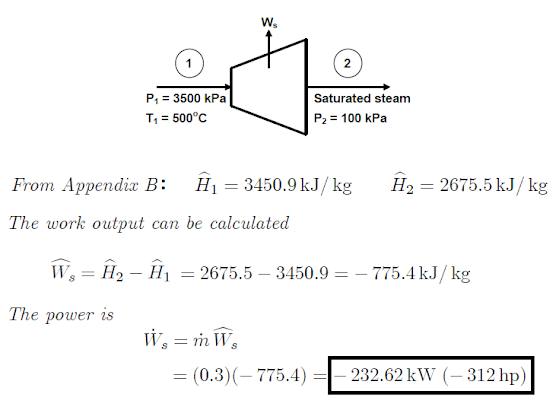

Note: For the following examples, Appendix B for steam values that I have referred to in these questions was obtained from:

M.D Koretsky, Engineering and Chemical Thermodynamics, Wiley, 2004.

Example 1

A fluid at 3.5 MPa and

350°C enters a throttling valve and leaves it at 100 kPa. Determine the exit

temperature if the fluid is (a) steam, (b) air.

Solution

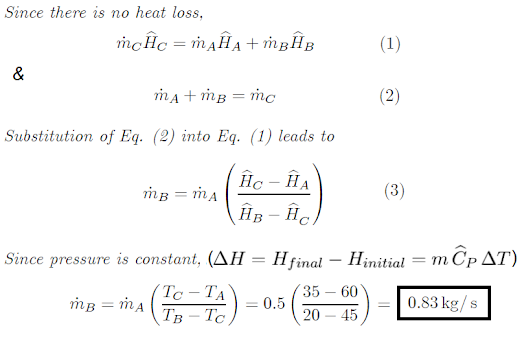

Example 2

Steam at 4.5 MPa and 500°C

enters the turbine with a velocity of 60 m/s and its mass flow rate is 5,000 kg/h.

The steam leaves the turbine at a point 3m below the turbine inlet with a

velocity of 350 m/s. The heat loss from the turbine is 105 kJ/h and the shaft

work produced is 950 hp. A small portion of the exhaust steam from the turbine

is passed through a throttling valve and discharges at atmospheric pressure.

What is the temperature of the steam leaving the valve?

Solution