There are several methods used to increase or decrease the temperature of a fluid. Heating of fluids is generally done using fuel fired furnaces through which the fluid in directed while cooling of fluids is done using chillers. Both of these methods require a significant amount of energy and expense to operate. Thus a cost effect method of heat exchange is needed.

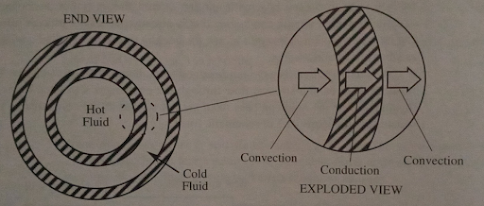

A heat exchanger is such a device, which is designed to exchange heat between two flowing streams (a hot one and a cold one). The streams in a heat exchanger are generally separated by a wall which conducts heat from the hot to cold stream. This principal is illustrated below:

Types of Heat Exchangers

a) Concentric-tube Heat Exchanger

It is the simplest form of a heat exchanger, which consists of one pipe surrounding another. The hot fluid can flow in the inner pipe while the cold flows in the outer pipe or vice versa. The general form of a concentric-tube heat exchanger is shown below:

A closer look inside the concentric-tube heat exchanger shows that heat transfer occurs through convection from hot fluid to pipe wall, then by conduction through the wall and finally convection from pipe wall into cold fluid. This is summarized below:

b) Shell and Tube Heat Exchanger

- The temperature gradient between the hot gases and the incoming gases.

- The total surface area of the tubes.

The figure below shows an illustration of a shell and tube heat exchanger. This heat exchanger is used in the used in the manufacture of sulfur trioxide from sulfur dioxide through the Contact Process where the excess heat warms incoming gases.

The figure illustrates the manufacture of sulfur trioxide. This exchanger is configured in a counter current flow mode. The fluid inside the shell actually slows across the outside of the tubes i.e., crossflow due to presence of baffles on the shell side.

c) Parallel-plate Heat Exchanger

In this type, the cold and hot fluids flow on opposite sides of conducting barriers in narrow spaces between the parallel plates.

Factors affecting the performance of a Heat Exchanger

- The rate of heat transfer determines the size of a heat exchanger.

- When a chemical reaction occurs within the exchanger (like a reactor) then the residence time also needs to be considered in the design of a heat exchanger.

- The direction of fluid flow. When the cold and hot fluids enter from the same direction along the exchanger, the arrangement is called co-current or parallel flow. In this arrangement the maximum temperature difference between the two fluids is at the point of entry and the temperature difference significantly decreases as the fluid moves along the exchanger. This is summarized below:

When the hot and cold fluids enter from opposite sides then this is called counter current flow. In this arrangement the temperature difference between the two fluids doesn't vary as dramatically as in the co-current flow. Also, in counter current flow, the exit of the cold fluid may be hotter than the exit of the hot fluid. This is summarized below:

The decision of whether to use co-current or counter current flow is based on which of the two yields in the smallest heat exchanger to transfer a specified amount of heat. Practical issues like piping layout also affect the decision. However, most heat exchangers use the counter current flow.

Sometimes, the fluid flowing in a shell and tube heat exchanger passes from one tube end to another only once same with the fluid in the shell side. This is called a single-tube pass, single-shell pass exchanger. But it is possible to configure an exchanger to have more than one tube and shell pass as illustrated below: